Liquid Level & Gas Tank Monitoring Solution

StockVUE is one of the world's first autonomous tank monitoring solutions to help users monitor fluid levels and get alerted when it's time to replenish the tank before it runs out. It uses smart scales to weigh the contents of the tank and upload data to the Cloud for access anytime, from anywhere, on any device! Get alerts via email or text messages and make sure your critical items Never Run Out!

How Does Fluid Level Monitoring Solution Work?

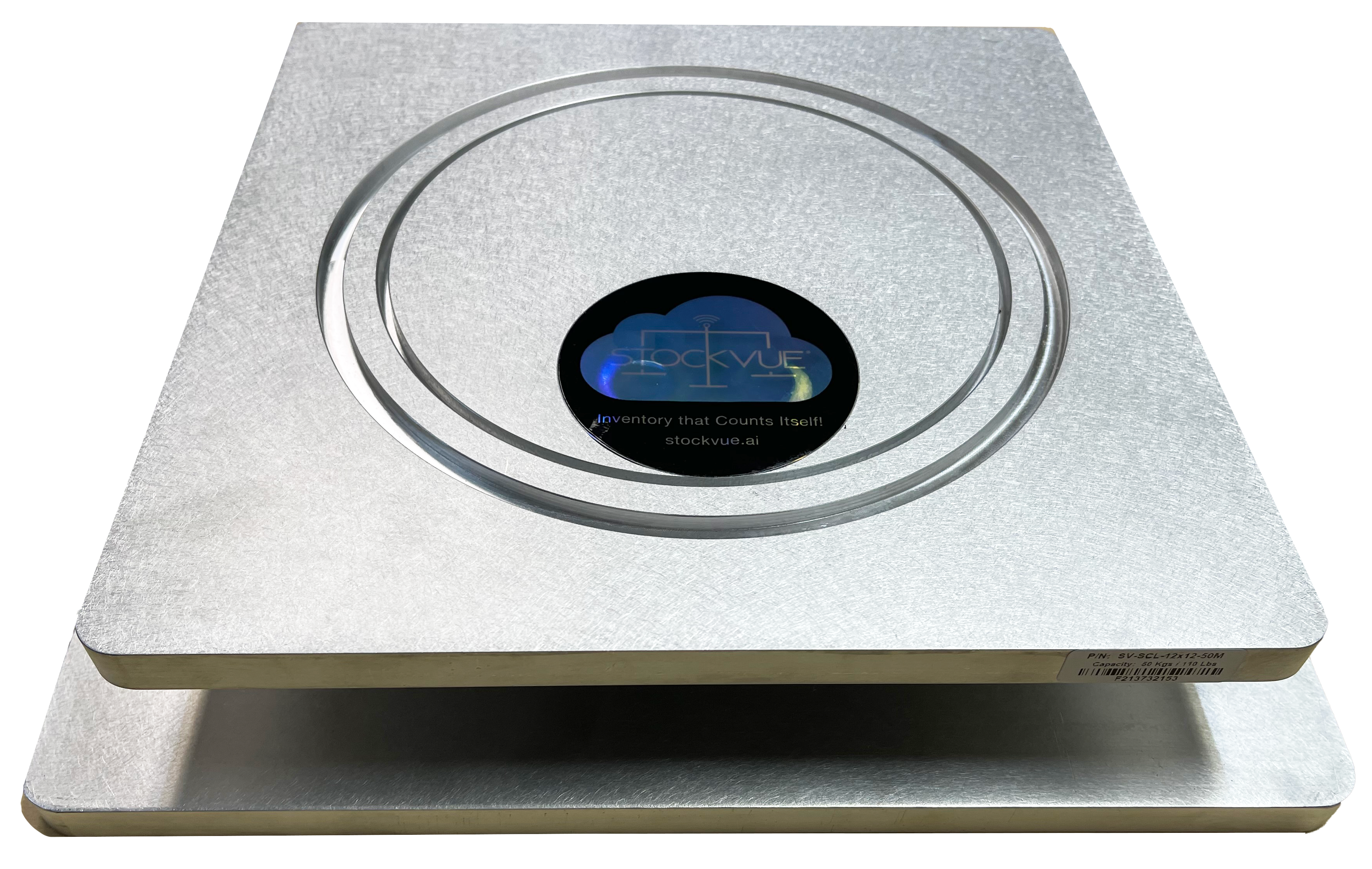

Smart scales with digital UART/USB Output are used to weigh the tanks. These rugged smart scales are available in various capacities and sizes and offer high accuracies of the order of +/- 0.1% of full scale from -10C to 40C.

Tare the scale with an empty tank and place the tank on the scale. Connect the scale to the Node+ and the Node+ to the Internet and turn it on!

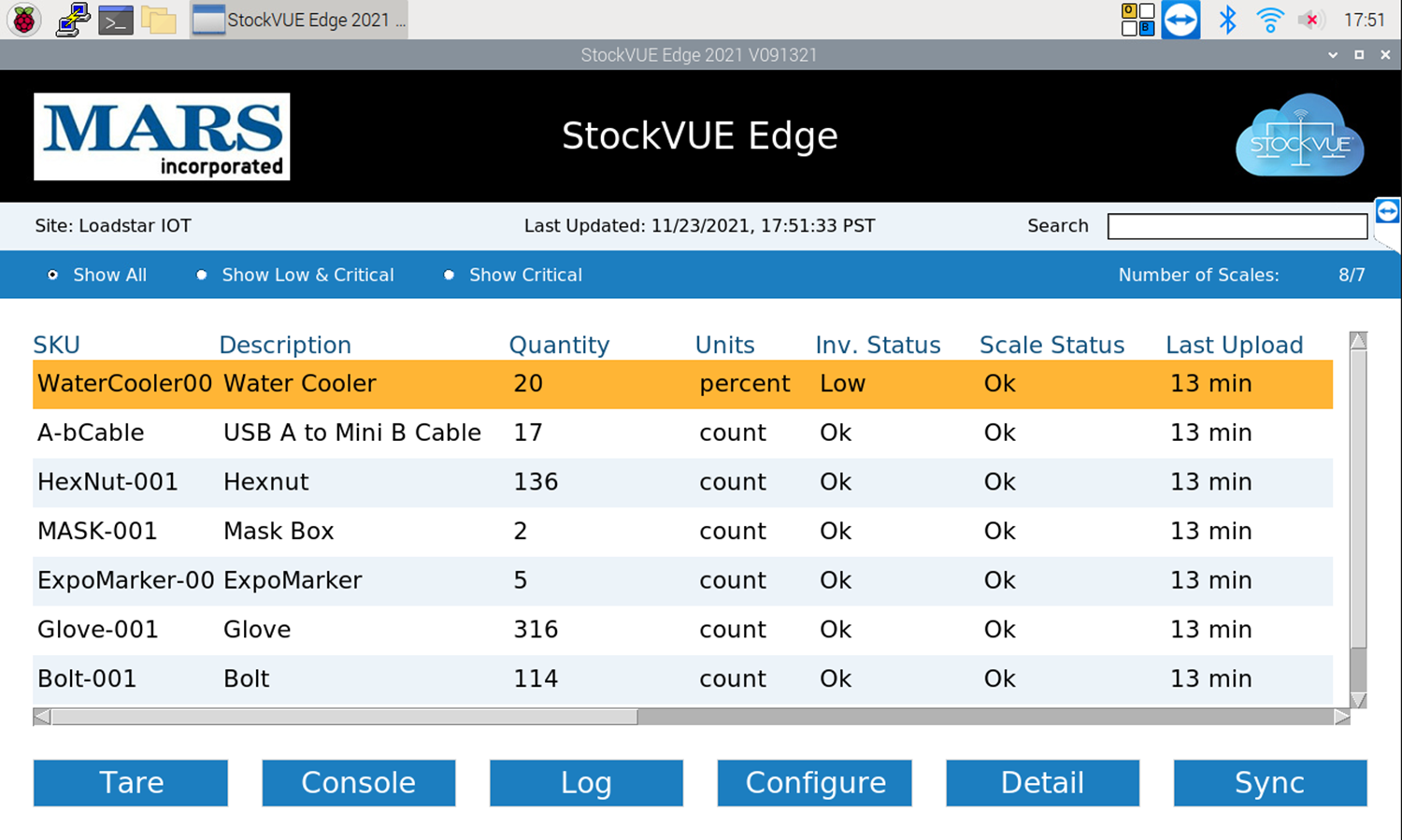

For more than 12 scales, add more routers as needed with up to 12 scales per router. All of the scales will be monitored and weights uploaded to the StockVUE cloud for further processing. StockVUE Cloud checks the weights against low or critical level settings and generates alerts and reports and send it out to designated personnel or suppliers.

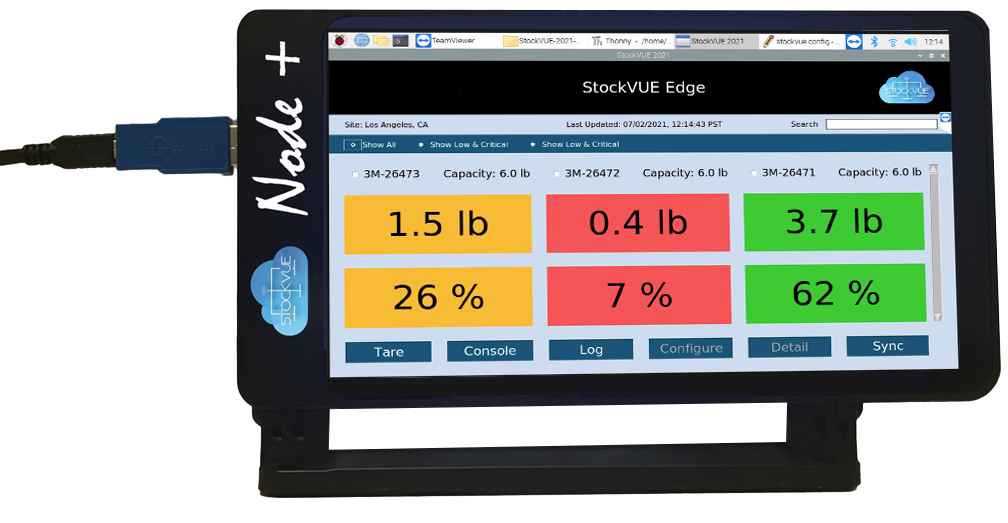

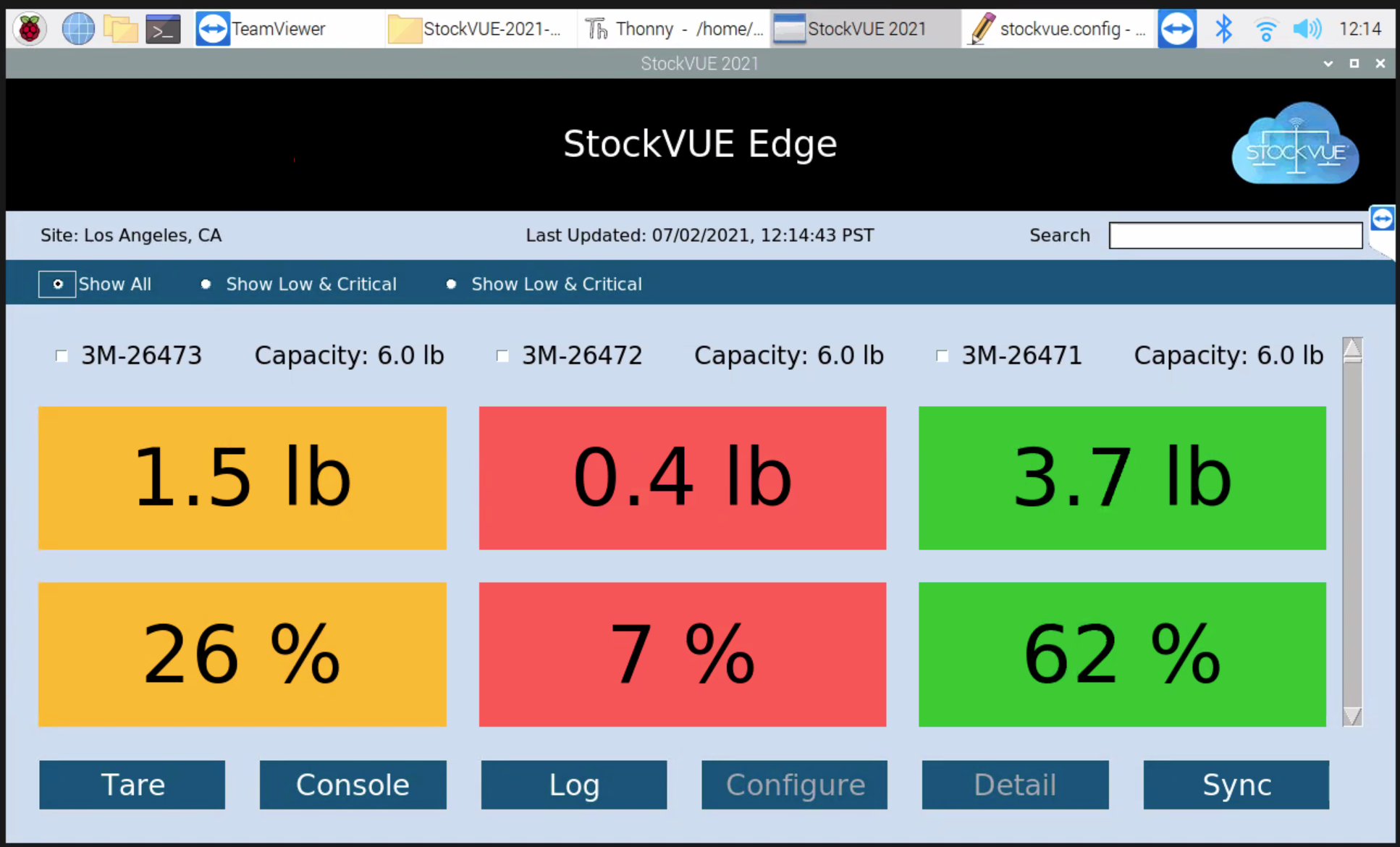

The Node+ IoT Gateway with a Touch Screen LCD acts as a local display as well as the conduit to upload data to the StockVUE Cloud.

The level of contents in the tank are now displayed locally as a weight or as percent of full scale. You can monitor up to four tanks using one Node+ connected directly via USB. For more scales, use a SC-1200Z wireless router to connect up to 12 scale. The wireless router connects to the Node+ gateway wirelessly and uploads data to the Cloud.

You can make this solution a part of yoru overall inventory management solution to handle discrete solid parts, powders, liquids or gases and monitor them all in real time, autonomously from anywhere in the world with a connected smart phone or computing device! Never Run Out of anything ever again!

Case Study

In a large, well established pharmaceutical company, the research team was having trouble ensuring an uninterrupted gas supply to their laboratory. Personnel had to go the gas supply chamber where gas cylinders are physically located and lift the cylinders to guess how much gas was remaining in the cylinder. The cylinders are heavy and lifting the cylinders presented a safety risk as well. Not having a constant gas supply could disrupt some critical laboratory procedures resulting in loss of valuable data and other resources. Keeping track of the levels of gas in cylinders was a manual, time consuming, and unscientific method that also possessed a safety risk.

The research team setup StockVUE's Fluid Level Monitoring solution and placed the gas cylinders on StockVUE scales, connected the scales to the power source, and to the IoT gateway and provided internet connection to the system. Now they can view the fluid levels in each of their cylinders right from their desk. The IoT gateway, Node Plus, displays the weight and percentage numbers on location and also transmits the data to the cloud.

Customer Reviews

We love that data is on our finger tips. Don't need to go to the loacation to see the real time inventory. Everyone can be on the same page and there won't be any supply issues. The analyst doesn't have to spend time to keep track of inventory. It will be available to them right away. It is very easy for everybody to use and has a lot of potential.

Right now our process is manual and sometimes ordering takes time. Some items are very heavy and the techinician has to lift it (the cylinder) up to see if it is empty. It is a safety issue. We wanted to see how we can make this process automated. StockVUe helped us achieve this goal.